Flow Amplifier Family

Flow Amplifier Family

Flow products are under continuous development. Originally, our customer requested a device house design for high end products. When designing the case, the main technologies used are 3D visual design, plate machining, bending and low temperature welding. The prototype housings were provided with extra bracing and were presented to our customer in powder paint.

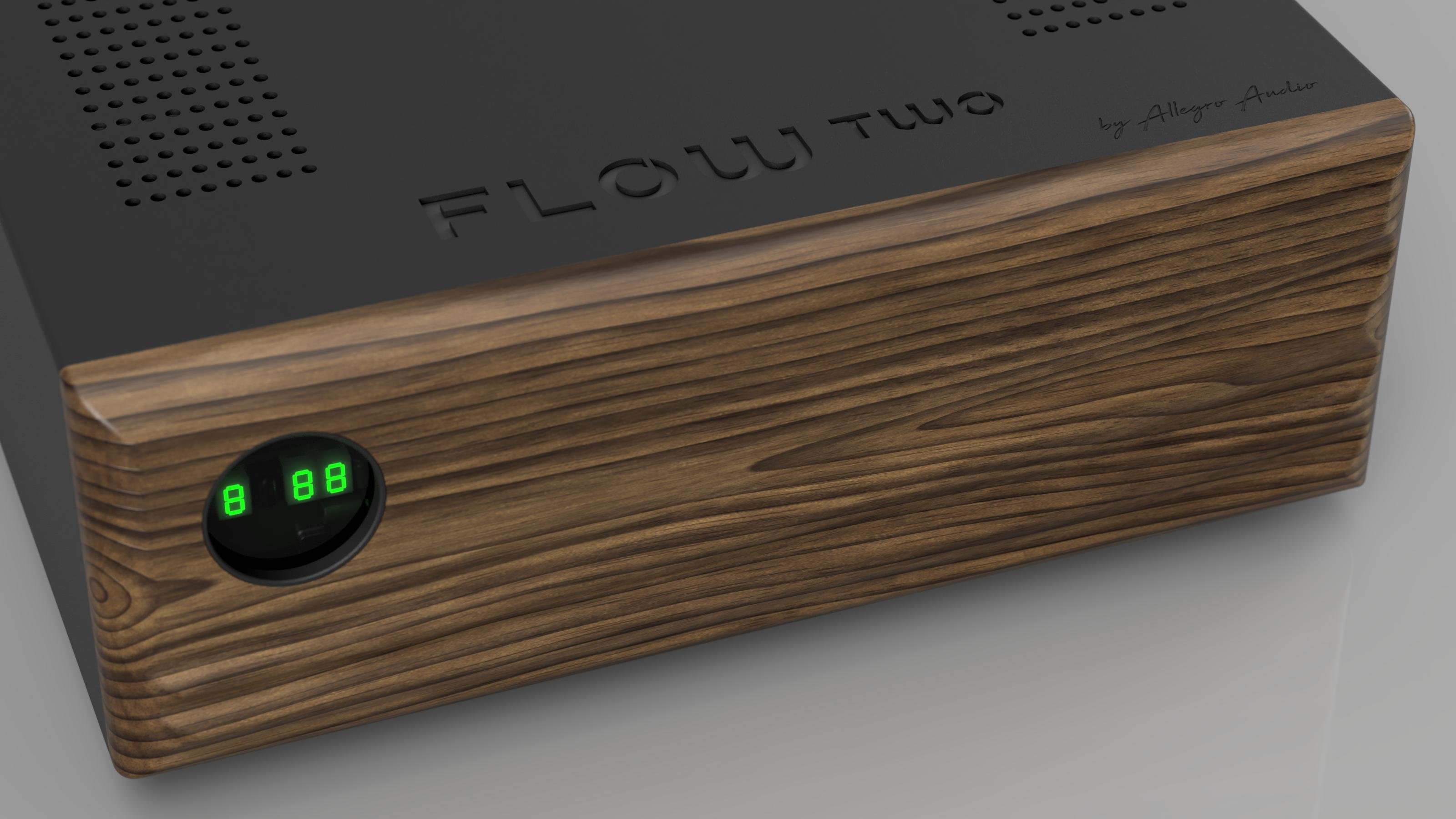

The customer has contacted us again. They wanted a unique wooden front panel, and they could not make them with traditional carpenter work. The three different products, Flow One, Flow Two, and FLow Three, had to be designed with the same technology, yet a unique pattern of wooden front panel. In its ambiance, the patterns have to imitate the mood of the waves, the mountains and the forest. Another challenge was that the three products are different in size, so the samples must be modeled at 100, 150 and 200 mmm height.

After the front panels were completed, the customer made a new request. The wooden case had a circular display, and the designer had dreamed a metal ring around the display. During the new discussions, the entire sample was redesigned for small-scale series production. The welding of the new inner reinforcement rib had to be solved by a unique method so that the material does not deform due to heat.

We received orders for two additional products. For the amplifiers, wooden knobs were made from a single piece of wood for vibration damping, and we developed a unique remote for the products. The production of all items takes 8-10 net work hours.

At the end a simple housing design became a complete product development project.