Unique workpieces and prototypes

2D and 3D laser cutting, laser welding, plate bending even in small number of copies.

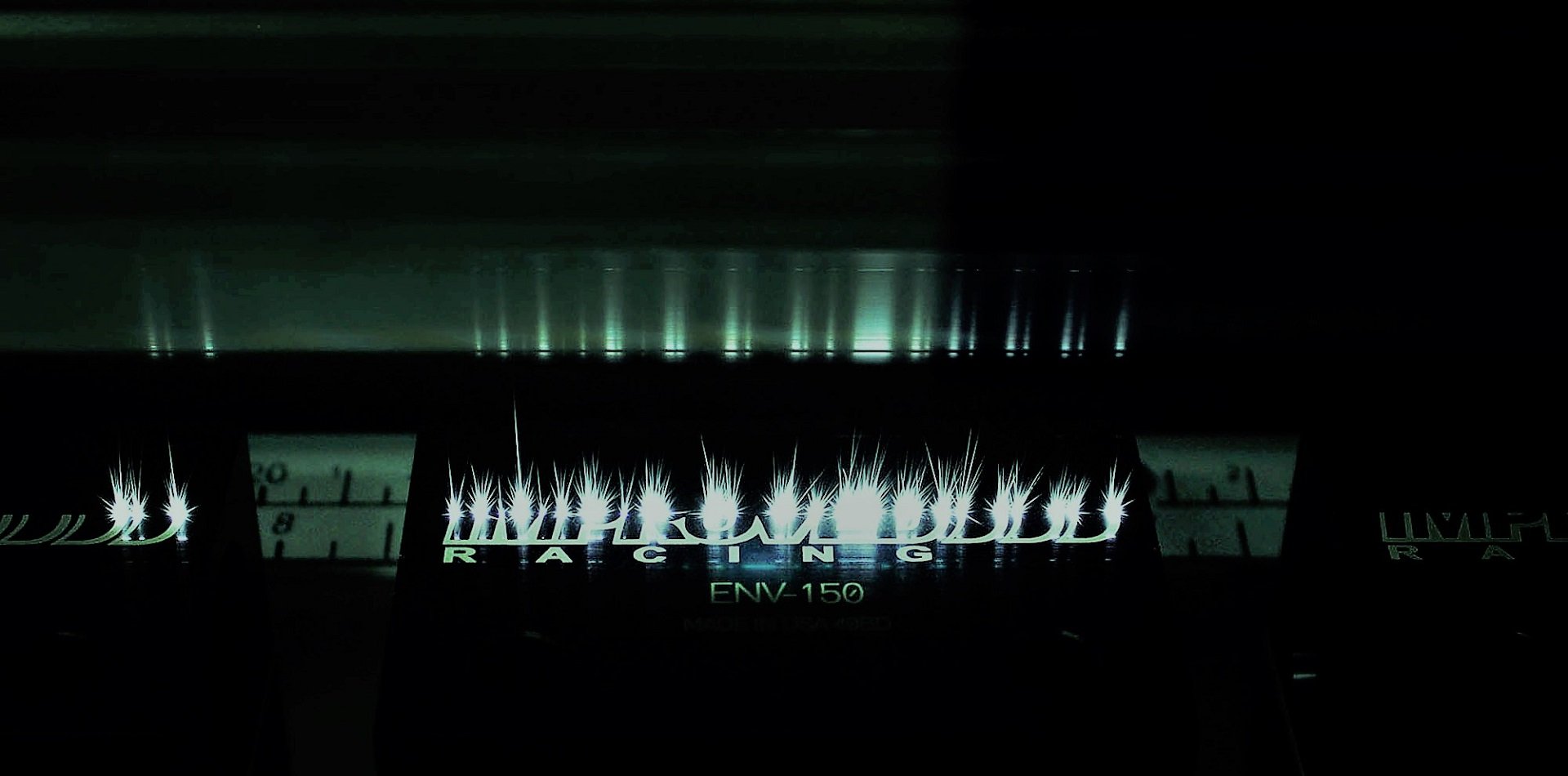

Laser engraving of graphics

Laser engraving of graphics on almost any metal.

Precise, full-featured production

Our colleagues are more than happy to help with advice, models, blueprints, manufacturing technology and so forth.

Our Solutions

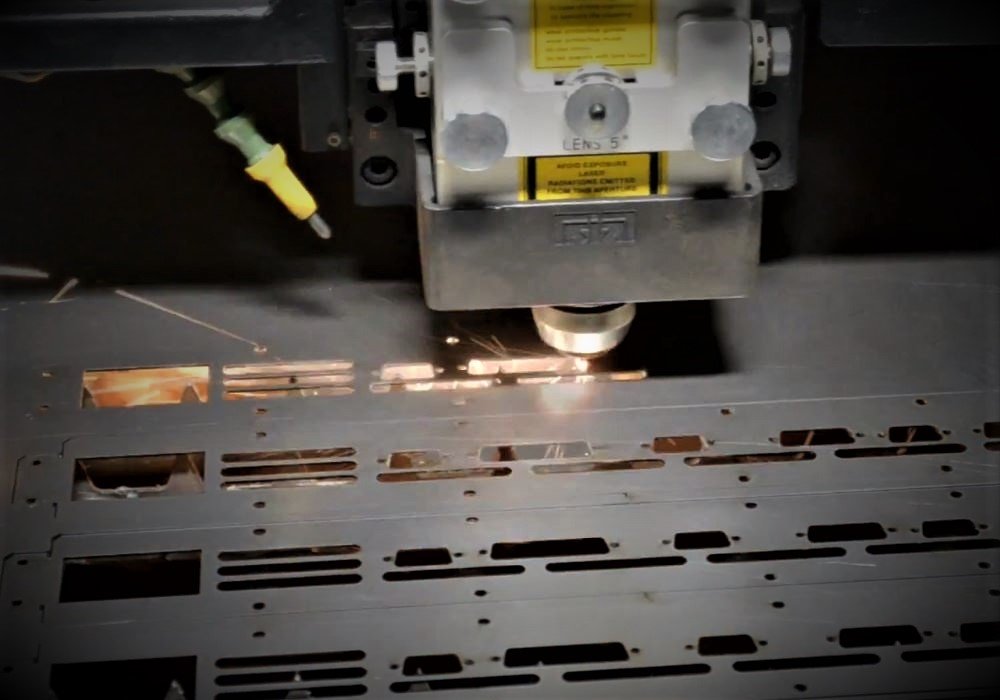

3D Laser cutting

Equipment: Prima Optimo (5 axis 3D laser) Performance: 3 000 W Dimensions: 4000 x, 2000 x 750 mm, A: 360°, B: +/-120° Cutting thickness: Steel: 10 mm Stainless Steell: 5 mm Aluminium: 4 mm We undertake the delivery and purchase of workpieces and raw materials based on preliminary consultation.

2D Laser cutting

Equipment: Prima Platino 2D laser Performance: 4000 W Dimensions: X:3000 mm (6000 mm), Y:1500 mm Cutting Thickness: Carbon Steel: 20 mm Stainless Steel: 12 mm Aluminium: 10 mm We undertake the delivery and purchase of workpieces and raw materials based on preliminary consultation.

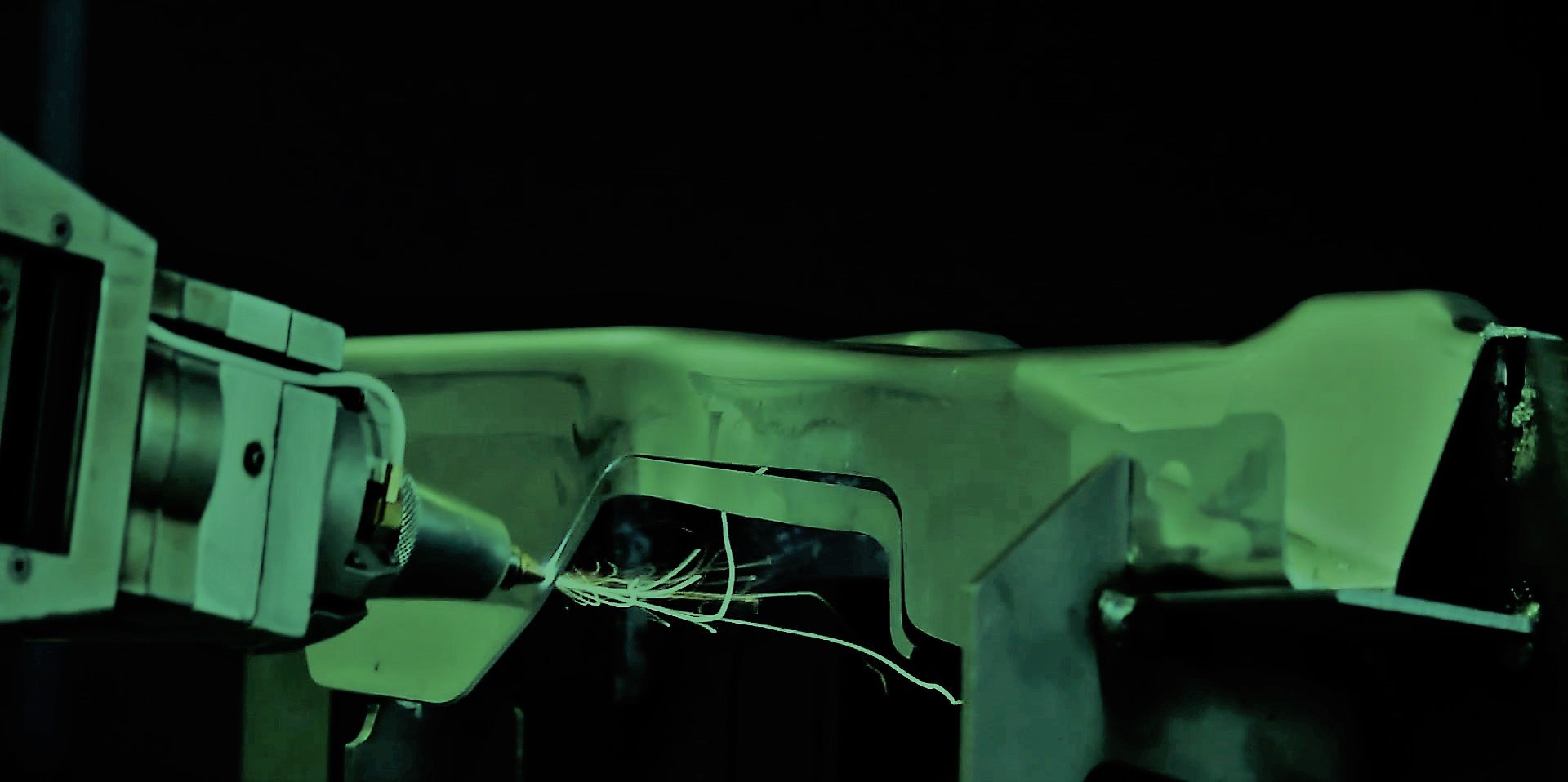

Laser welding

Equipment: YAG, direct beam laser We can perform spatial welds without any geometrical barriers, with the least possible thermal load and minimal deformation with high quality welding seams up to a width of 0.3 to 1.5 mm. We undertake the delivery and purchase of workpieces and raw materials based on preliminary consultation.

Laser marking (engraving)

Our YAG, Galvo-type laser engraving equipment offers a solution for marking almost any metal-based material. Equipment: Foba Vario RD 50 Performance: 50 W Dimensions: X:120 mm, Y:120 mm, Z:200 mm Weight: max. 16 kg Equipment: Foba G5 Performance: 100 W Dimensions: X: 500 mm, Y: 500 mm, Z: 500 mm Weight: max. 100 kg

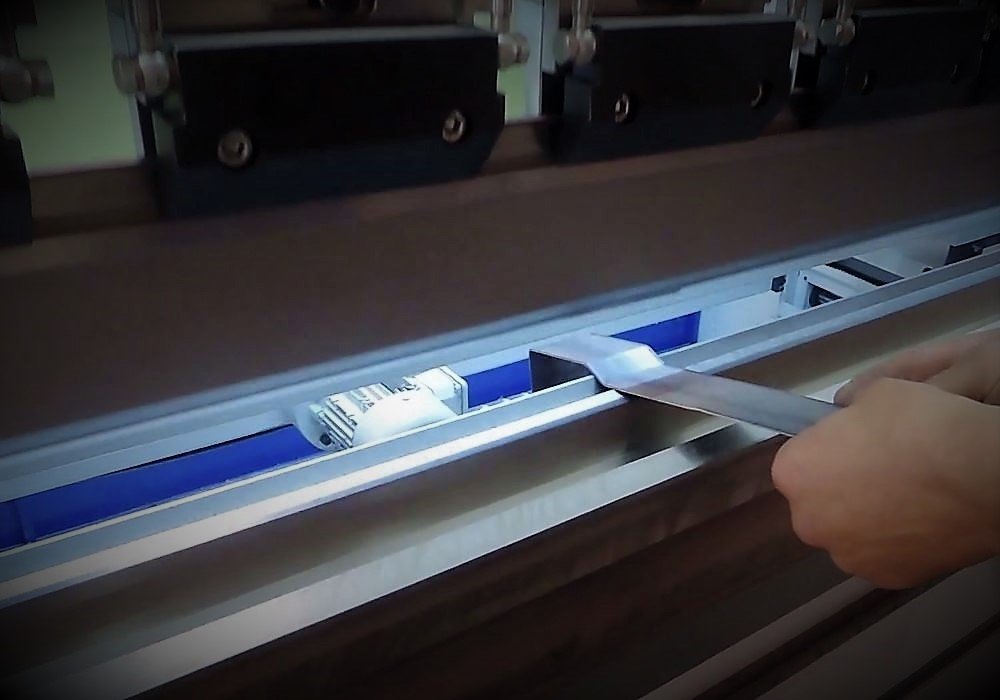

Bending

Equipment: Marla Machinery HAP 220T 9 axis bending machine Dimensions: 3000 mm Bending Thickness (on 3000 mm lenght): Carbon Steel: 10 mm Stainless Steel: 8 mm Aluminium: 15 mm We undertake the delivery and purchase of workpieces and raw materials based on preliminary consultation.

Milling, drilling

Equipment: Yonghua V10L Performance: 11/15 kW Dimensions: 1160 mm × 600 mm Max Weight Load: 800 kg Range of motion: 3 axis: 1000 x 600 x 600 mm Spindle type: BT40 Spindle speed: 10000 rpm Materials: Steel, aluminium, plastic We undertake the delivery and purchase of workpieces and raw materials based on preliminary consultation.

Why are we better choice than others?

Flexible possibilities, creative solutions

Be it any cutted folded or welded workpiece, we can produce it, thanks to our state of the art equipment and engineer staff.

Full assistance

We even help in the planning, our staff can make full production plans based on the discussed idea and concept, and in many cases we solve the transportation of the raw workpieces too.

Cost-efficient production for small number of copies too

We can produce unique sized or shaped workpieces for relatively lower cost, thanks to your special machines.